sustainability as a CHOICE

Teerenpeli Distillery has been planning it´s actions in sustainable way for several years. We have reduced our carbon footprint with our own wood pellet power plant since 2015 and use the closest possible ingredients in our production. Most of the malted barley we use has grown within 150 km from the distillery since the beginning in 2002. Here you can read more of our sustainability actions.

”We must take care of the environment for the next generations to follow us.” -Anssi Pyysing, CEO & founder of Teerenpeli Distillery

Using the pellet plant as an energy source

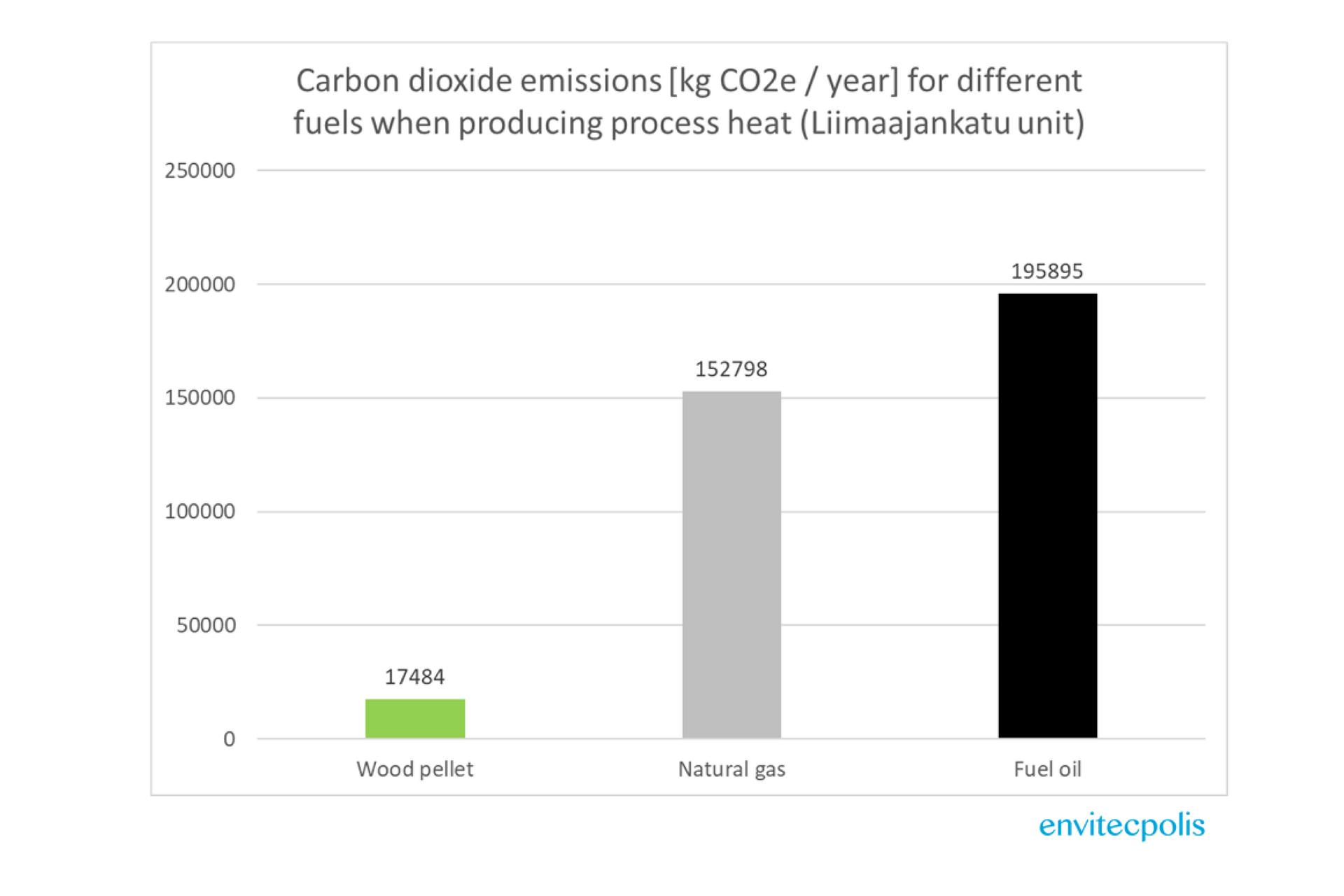

We use our own wood pellet power plant to produce the process heating needed for Teerenpeli Brewery & Distillery production operations. The wood pellets used in our power plant are made from residues of Finnish saw mills. By using these wood pellets as our energy source, we are reducing our carbon footprint roughly by 90 % compared to the more traditionally used fossil energy sources.

Purpose

Here in Teerenpeli we have used our own wood pellet power plant for the brewery and distillery production since 2015. By choosing the wood pellet as an energy source, we wanted to choose the power that uses renewable energy and has a smallest possible climate impact.

Our wood pellet power plant was built in 2015 and it has sourced the production energy for Teerenpeli Brewery & Distillery ever since. After its installation the impact for climate has been approximately only 10 % compared to other energy sources, such as oil or gas.

Results

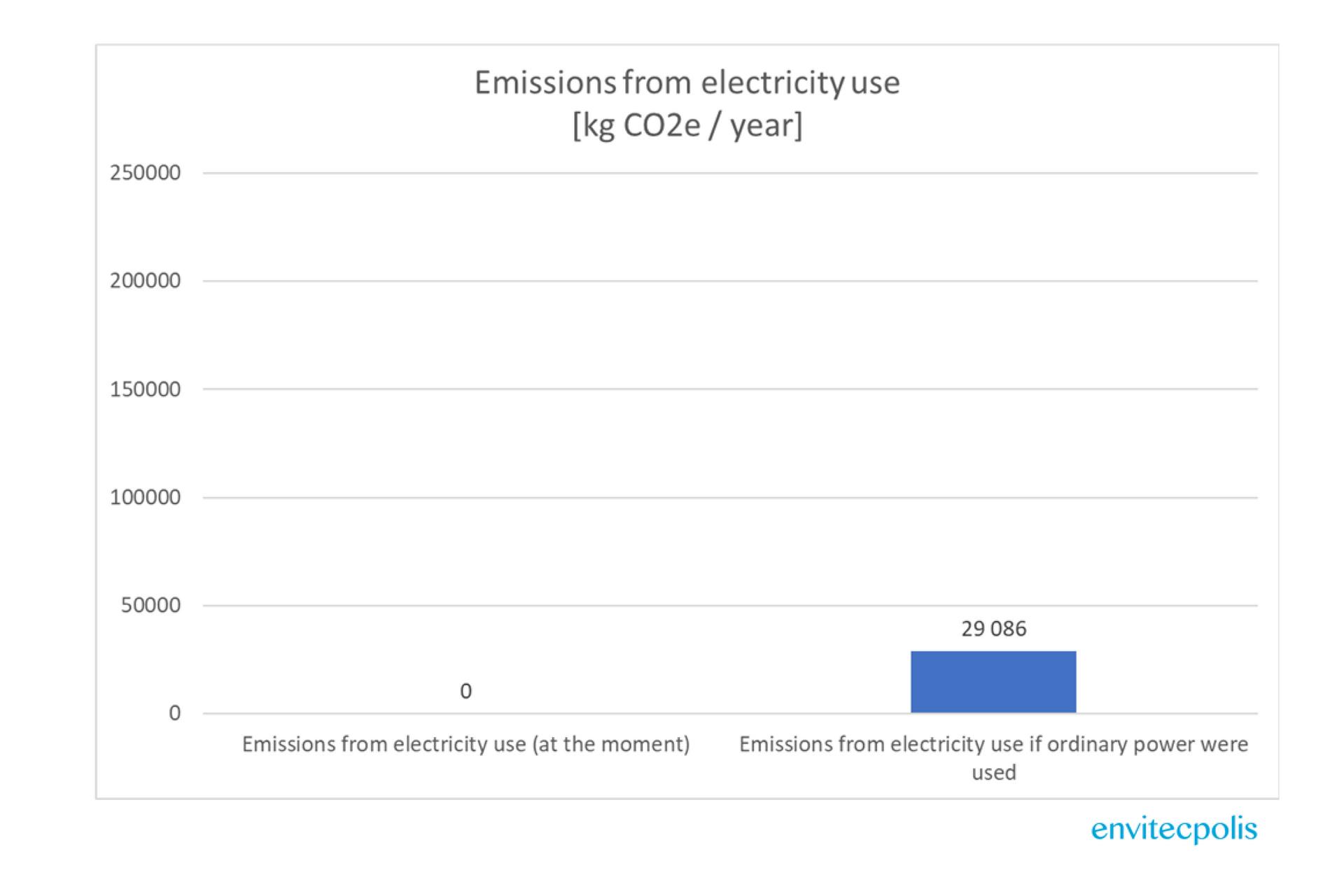

Teerenpeli´s wood pellet energy plant produced 730 MWh renewable energy for the production in 2019. The production used also 220 MWh renewable wind and water electricity.

The yearly climate impact for the wood pellet plant is only 17 484 kg CO2e / year. This is only 11,4% compared if the energy source would be natural gas and only 8,9% if we would use oil as a energy source. The impact for climates is already 950 000 kg CO2e smaller compared to natural gas energy and 1 250 000 kg CO2e smaller compared to oil energy.

Implementation

Brewing and distilling process requires plenty of hot water, which in turn means high energy expenditure to reach the needed temperatures. To achieve this in an environmentally sustainable way, we at Teerenpeli chose to build our own pellet power plant. This way we have been able to produce our process heat renewably, especially since the pellets we use are made from a residual saw dust of a local saw mill. Not only this, but the electricity we use in our production has also been produced renewably, from wind and water power plants.

Carbon footprint

Teerenpeli Distillery had a carbon footprint calculation project at the end of 2021. The results revealed the carbon footprint of our products. These results work as a guideline for us to work all the time with more sustainable way. The results showed us that the decisions we have made throughout the years have been good, but of course there is also a lot to do better. Please, follow up for our news and social media to updates we make about this important matter.